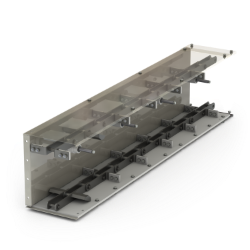

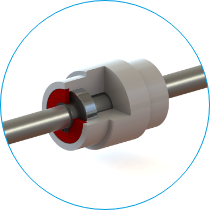

In standard systems, we use the return of the chain after the rollers. Made of PA6G plastic, it guarantees long-term reliability in typical operating conditions. The intermediate trough with a length of 1900 mm is equipped with four rollers: one guide, stepped with a centering ridge and three smooth rollers. The design of the roller mounted on the steel axis allows it to be easily replaced without having to disassemble other elements of the conveyor body.

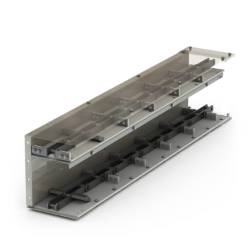

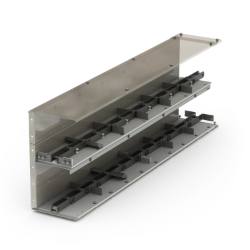

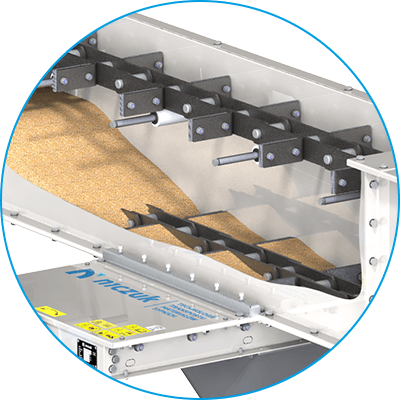

Thanks to the double bottom design, rounded plates used at the ends of the drive station and the return station, the conveyor allows material (e.g. wandering on the flat surfaces of the chain) to be transported to the upper deck. Then the material is transported towards the return station to once again go to the appropriate chute. Rewinding the chain several times in the conveyor will clean it. The self-cleaning function plays an important role in the stricter technological requirements of transporting different materials on the same conveyor, mainly in forwarding systems. At the customer's request, buckets are welded to the chain.

It is used in installations with a large number of fills or in the case of dumps located before and after the fill. Thanks to the use of a high double bottom, it is possible to transport the material on the upper deck towards the return station, where it falls to the lower bottom and is then collected towards the drive station.

Conveyors designed to work in zones with an increased risk of explosion hazard 2D (EX 21 dust).

The guarantee of safe operation of devices in potentially explosive atmospheres is the ATEX certificate number OBAC 15 CZ/ATEX 0165.

Redler conveyors in the version adapted to work in conditions of increased explosion hazard are additionally equipped with:

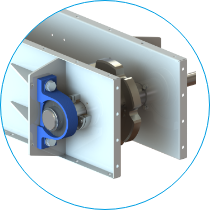

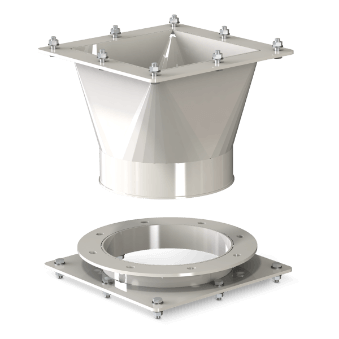

Our devices, regardless of their type series, can be equipped with fittings that enable trouble-free charging of the device, as well as its proper emptying. The connecting elements, made according to three termination standards, determine how they are installed in your piping system:

Fittings are available in standardized versions, as well as are made according to individual needs, adapted to the situation in your facility.

Our devices are used in the transport of bulk materials such as: grain, pulses and oilseeds, sawdust, fodder and biomass. They are most often used in oil mills, mills, feed mixing plants, port handling and grain and biomass warehouses.

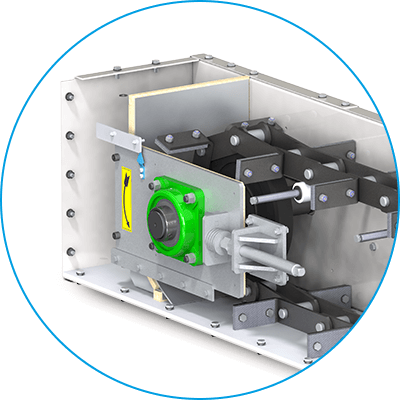

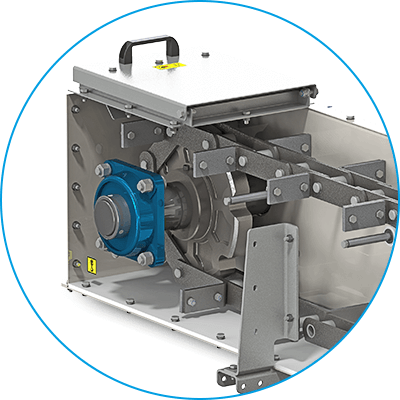

The evidence of NICZUK products quality is the most stable construction of the drive system, which guarantees reliable operation for years. Thick cross-sections of the materials used throughout the machine ensure the rigidity of the structure and reduce the noise generated during operation.

Depending on the medium, the conveyors can transport material at an angle of up to 20°. The devices use NORD and SEW gear motors. The offer includes conveyors with a capacity of up to 200 tons.

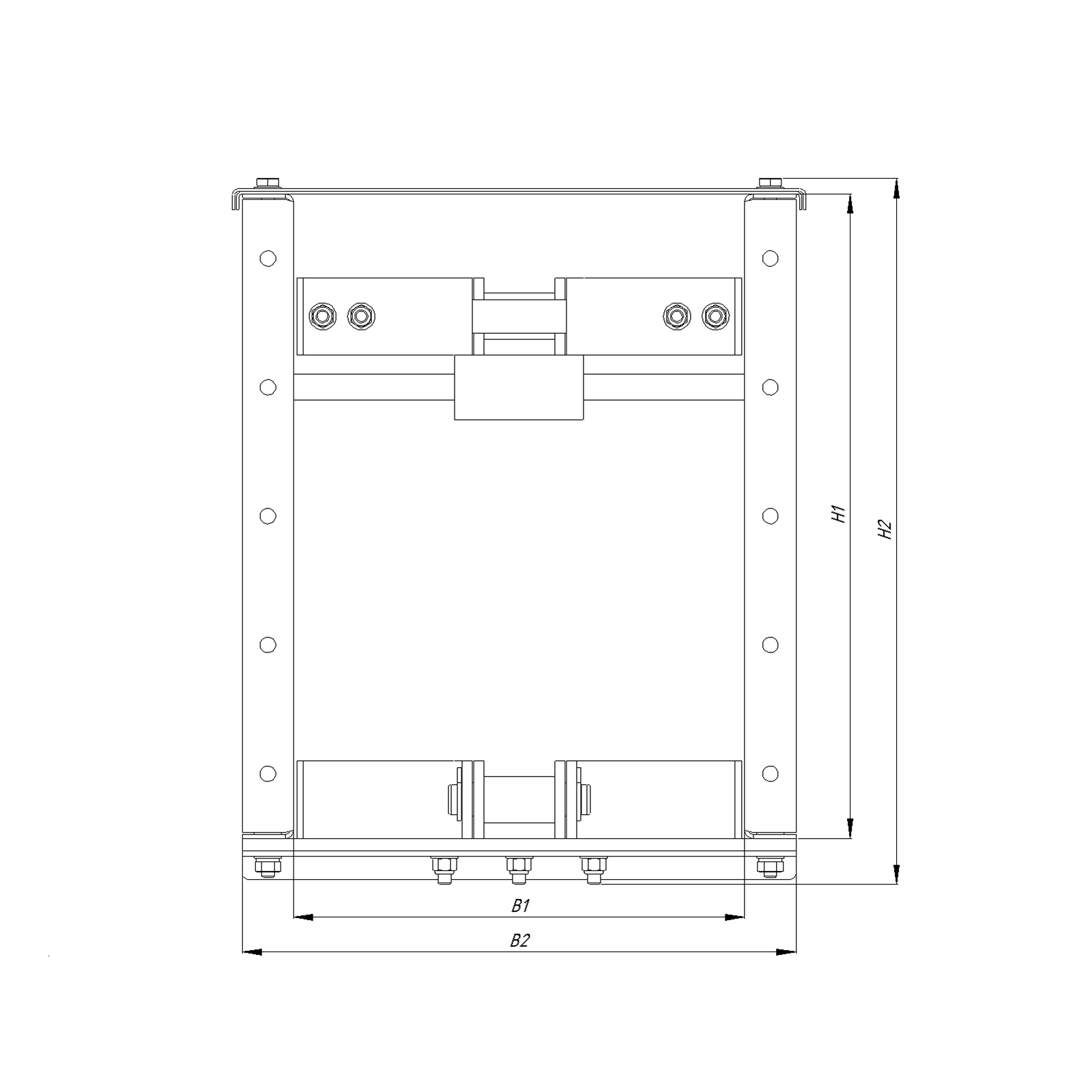

| Typ | Designation | Mass capacity for... | Volume capacity Q... | Trough inside dim... | Trough outside di... |

|---|---|---|---|---|---|

| 30E / 30 | SPR-030/030E | 15-40 | 20-53 | 200x320 | 280x364 |

| 50E / 50 | SPR-050/050E | 35-60 | 47-80 | 250x420 | 330x464 |

| 75E / 75 | SPR-075/075E | 60-75 | 80-100 | 30x420 | 380x464 |

| 100E / 100 | SPR-100/100E | 90-120 | 120-160 | 350x500 | 430x544 |

| 150E / 150 | SPR-150/150E | 130-160 | 185-213 | 400x500 | 480x542 |

| 200E / 200 | SPR-200/200E | 160-300 | 213-400 | 450x550 | 530x594 |

Thanks to our experienced team of designers we are able to carry out projects involving non-standard chain and screw conveyors as well as bucket elevators, gate valves, distributors and other devices from our offer. Also for transporting materials other than those listed above.