The position of the glider is determined by inductive sensors.

The position of the glider position is determined by contractor sensors.

At the customer's request, the gate valve can be equipped with a chain, facilitating its opening if located at a higher height.

We offer gate valves for tank and conveyor valves with ATEX II 2D and 3D certificates, enabling the installation of devices and safe operation in zones with an increased risk of explosive atmospheres Electrically controlled, pneumatically or manually compliant with the ZPR and NZZ series with components adapted to work in the EX zone

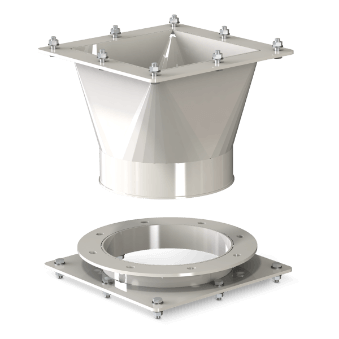

Our devices, regardless of their type series, can be equipped with fittings that enable trouble-free charging of the device, as well as its proper emptying. The connecting elements, made according to three termination standards, determine how they are installed in your piping system:

Fittings are available in standardized versions, as well as are made according to individual needs, adapted to the situation in your facility.

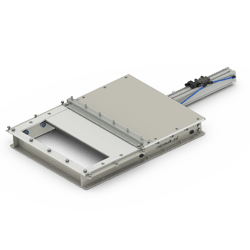

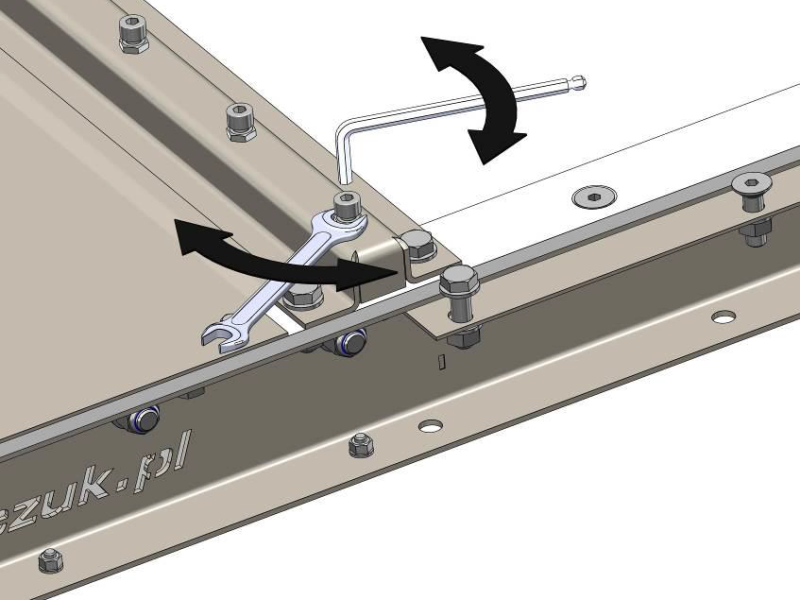

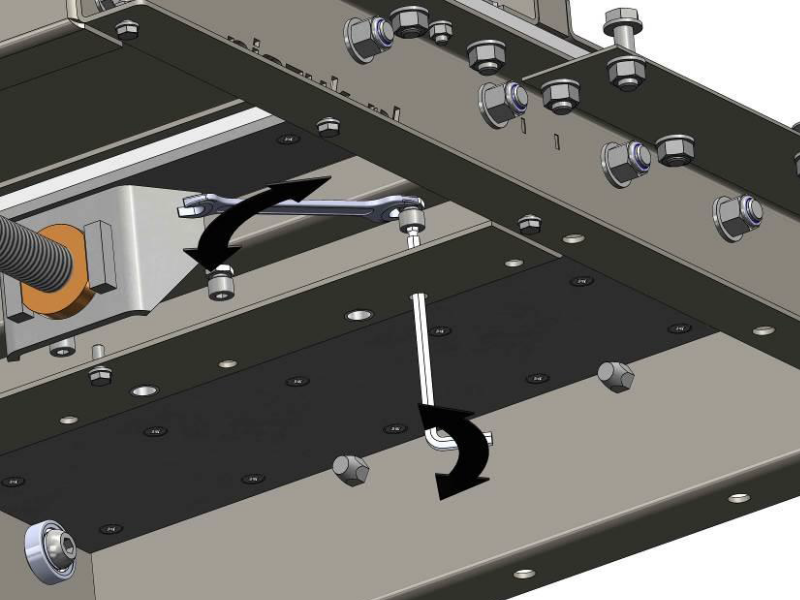

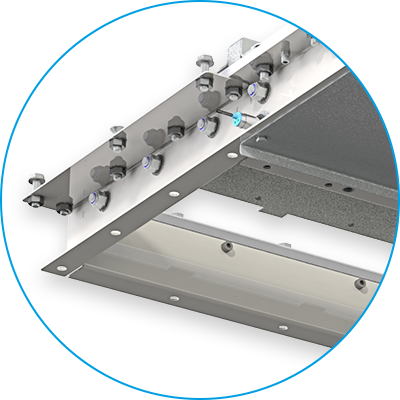

We have the only system on the market for adjusting the upper and lower rail pressing the gate valve sun. The applied solution significantly increases the dust-tightness of gate valves that meet even the highest hygiene requirements in mills, feed mills and other facilities where transport by Redler conveyors is used. The gate valve is equipped with double-sided seals with felt that the user can conveniently tighten using an Allen key. On 14 December 2015, we filed an application for patent protection of a new type of subredler gate valve.

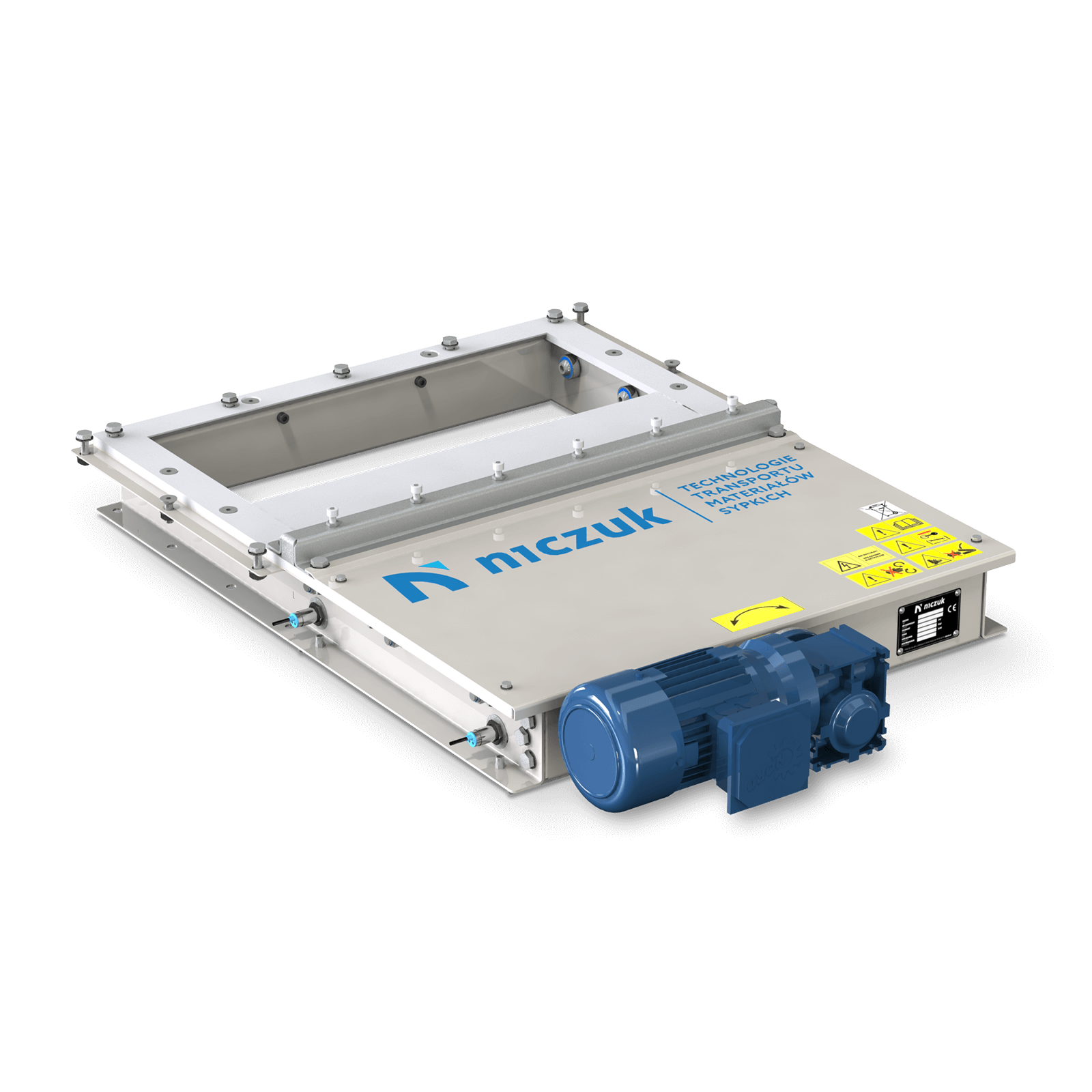

Subredler slade gates are used to control the stream of transported medium to appropriate transport routes, which enables full control over the production process. Their use in appropriate configurations, based on the experience of our clients, ensures proper flexibility of the process.

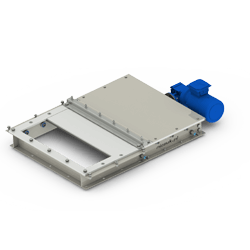

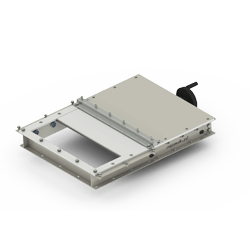

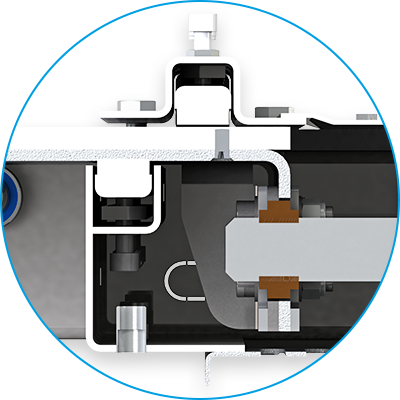

The gate frame is made of shaped sheet metal, previously cut with a laser. The closing plate used, with guides on ball bearings, prevents it from blocking due to dust. The control used in the gate valves can be mechanical, electro-mechanical or pneumatic. Pneumatic gate valves are equipped with HAFNER actuators as standard, while electric valves are equipped with NORD drives. Subredler gate valves are made in accordance with the series of manufactured conveyors (redlers). For manual and electric control, a trapezoidal screw and a special nut made of bronze are used, which prevent the slide from moving during operation. The gate valve shaft is lined with wear-resistant plastic, which allows the shaft to be flush with the bottom of the conveyor and extends the life of the device shaft.

Our under-redler slade gates are characterized by excellent tightness and, after their closure, create an even surface with the lift floor, which has a direct impact on the durability of the system.

| Typ | Designation | A [mm] | B [mm] | C [mm] | D [mm] | E [mm] | F [mm] | G [mm] | H [mm] | I [mm] | J [mm] | K [mm] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | ZPR-030-E | 200 | 500 | 280 | 575 | 750 | - | - | 215 | 100 | 580 | 640 |

| 30 | ZPR-030-R | 200 | 500 | 280 | 575 | 750 | - | - | 160 | 100 | 580 | 640 |

| 30 | ZPR-030-P | 200 | 500 | 280 | 575 | - | 900 | 120 | - | 100 | 580 | 640 |

| 50 | ZPR-050-E | 250 | 500 | 330 | 675 | 680 | - | - | 215 | 100 | 580 | 640 |

| 50 | ZPR-050-R | 250 | 500 | 330 | 675 | 680 | - | - | 160 | 100 | 580 | 640 |

| 50 | ZPR-050-P | 250 | 500 | 330 | 675 | - | 1050 | 120 | - | 100 | 580 | 640 |

| 75 | ZPR-075-E | 300 | 500 | 380 | 775 | 950 | - | - | 215 | 100 | 580 | 640 |

| 75 | ZPR-075-R | 300 | 500 | 380 | 775 | 950 | - | - | 160 | 100 | 580 | 640 |

| 75 | ZPR-075-P | 300 | 500 | 380 | 775 | - | 1200 | 120 | - | 100 | 580 | 640 |

| 100 | ZPR-100-E | 350 | 600 | 430 | 875 | 1050 | - | - | 215 | 100 | 680 | 740 |

| 100 | ZPR-100-R | 350 | 600 | 430 | 875 | 1050 | - | - | 160 | 100 | 680 | 740 |

| 100 | ZPR-100-P | 350 | 600 | 430 | 875 | - | 1350 | 120 | - | 100 | 680 | 740 |

| 150 | ZPR-150-E | 400 | 600 | 480 | 975 | 1150 | - | - | 215 | 100 | 680 | 740 |

| 150 | ZPR-150-R | 400 | 600 | 480 | 975 | 1150 | - | - | 160 | 100 | 680 | 740 |

| 150 | ZPR-150-P | 400 | 600 | 480 | 975 | - | 1500 | 120 | - | 100 | 680 | 740 |

| 200 | ZPR-200-E | 450 | 600 | 530 | 1075 | 1250 | 1650 | 120 | 215 | 100 | 680 | 740 |

| 200 | ZPR-200-R | 450 | 600 | 530 | 1075 | 1250 | 1650 | 120 | 215 | 100 | 680 | 740 |

| 200 | ZPR-200-P | 450 | 600 | 530 | 1075 | 1250 | 1650 | 120 | 215 | 100 | 680 | 740 |

Thanks to our experienced team of designers we are able to carry out projects involving non-standard chain and screw conveyors as well as bucket elevators, gate valves, distributors and other devices from our offer. Also for transporting materials other than those listed above.