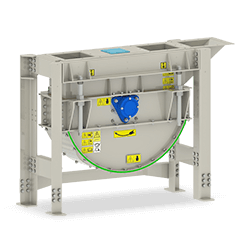

"Classic" execution of the elevator foot, allowing to obtain optimal infeed heights. The foot is equipped with cleaning sheets and visors.

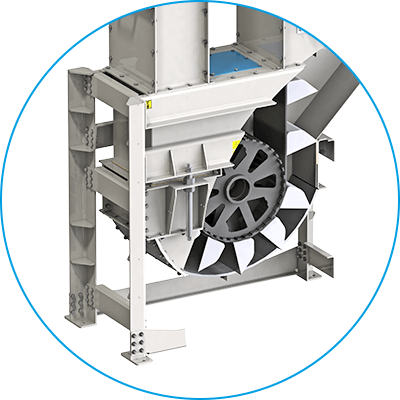

A special design of the foot, allowing to maintain a constant distance of the band wheel relative to the bottom. This guarantees maximum cleanliness of the system by eliminating the retention of residual material. Periodic servicing of the foot can be done using two-way audit accesses

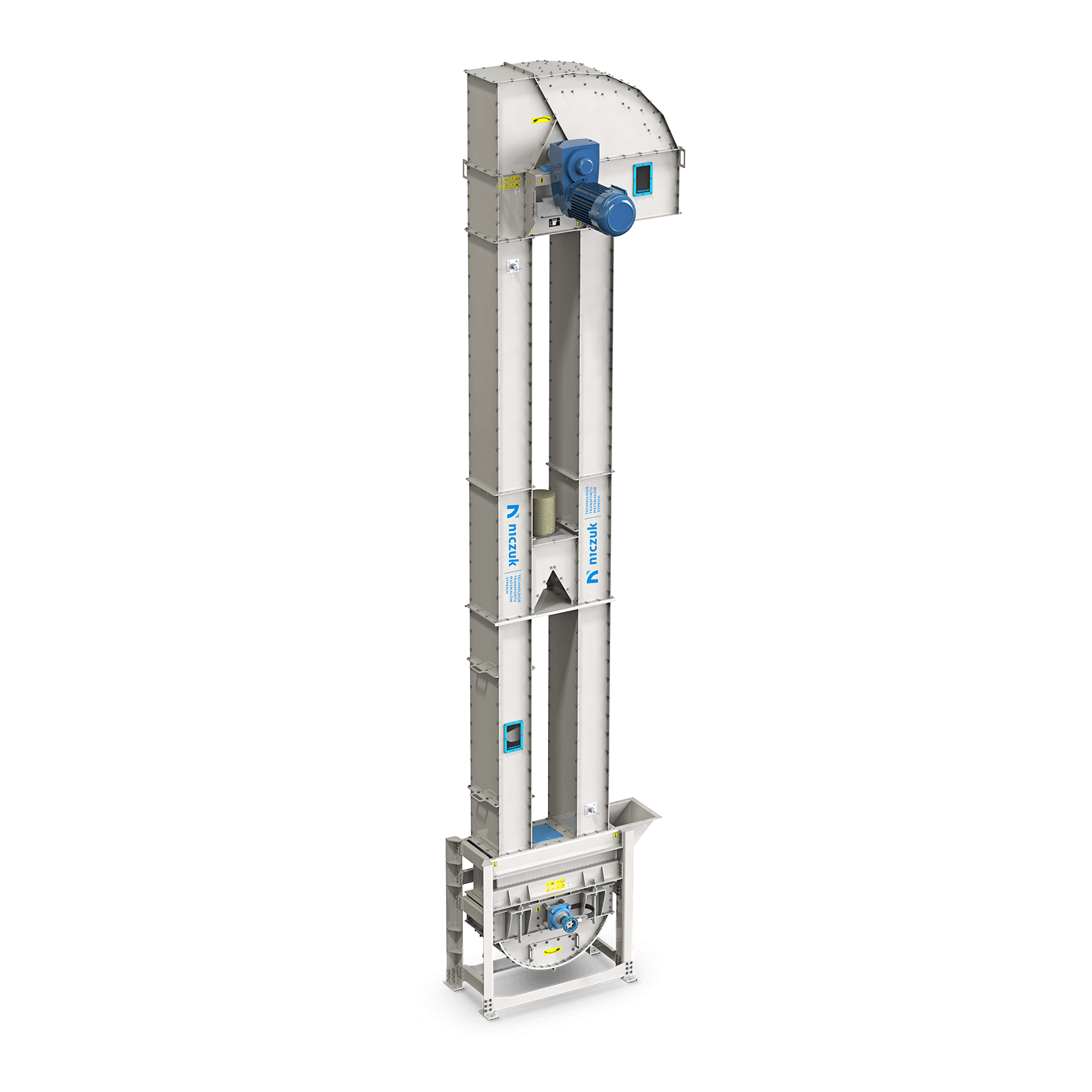

The bucket elevator is used for vertical transport of raw materials such as: cereals, legume and oilseed seeds, fodder, flour.

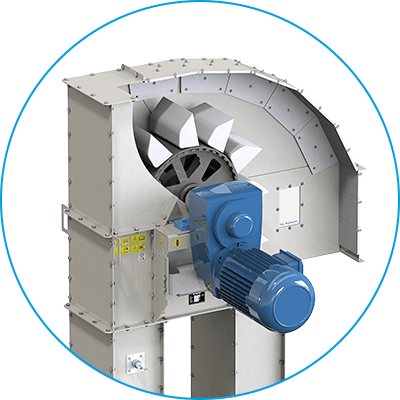

Leading design solutions - the gurt belt is tensioned on both sides. Openwork barrel wheels prevent sticking and center the position of the belt. In addition, the wheels in the foot are equipped with ejection blades responsible for self-cleaning the space inside the wheel. Openwork wheels significantly reduce material damage and wear of belt and bucket assembly. Ergonomic operation - Transport pipes are made of four edged walls connected by screws, which allows free service access. The body of the eloevator is equipped with numerous inspection windows and hatches. Dust aspiration - the foot and head are adapted to the installation of aspiration points (filters), thus the vacuum that may arise in the elevator is reduced. With the required mechanical aspiration (dust cabinet), transport pipe connector equipped with connection connections for filter assembly is used.

Elevators are made in the performance series, ensuring smooth operation of the line transporting raw materials. They are characterized by excellent tightness, durability and thoughtful solutions.

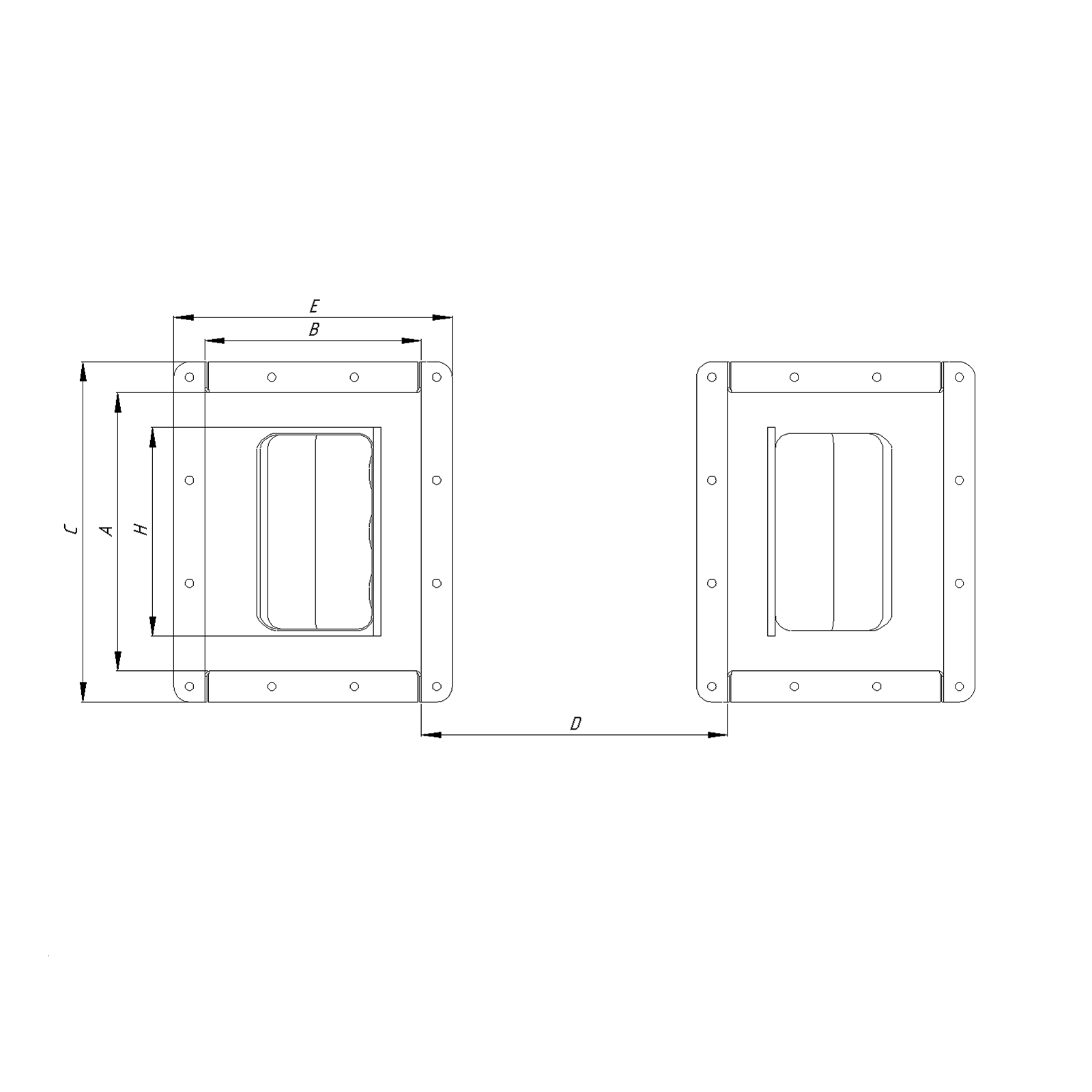

| Typ | Designation | Mass capacity for... | Volume capacity Q... | Number of buckets... | Belt width H [mm] | Elevator wheel di... | A [mm] | B [mm] | C [mm] | D [mm] | E [mm] | H [mm] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | NPK-010 | 0,75-15 | 1-20 | 8 | 120 | 300 | 180 | 176 | 260 | 236 | 256 | 120 |

| 30 | NPK-030 | 15-42 | 20-56 | 7 | 160 | 500 | 215 | 200 | 295 | 396 | 280 | 160 |

| 60 | NPK-060 | 42-75 | 56-100 | 7 | 220 | 500 | 300 | 250 | 380 | 396 | 330 | 220 |

| 100 | NPK-100 | 75-120 | 100-160 | 7 | 270 | 500 | 360 | 260 | 440 | 396 | 340 | 270 |

| 150 | NPK-150 | 120-176 | 160-235 | 5 | 330 | 500 | 400 | 330 | 480 | 396 | 410 | 330 |

| 200 | NPK-200 | 176-247 | 235-330 | 6.25 | 400 | 630 | 480 | 340 | 560 | 522 | 420 | 400 |

Thanks to our experienced team of designers we are able to carry out projects involving non-standard chain and screw conveyors as well as bucket elevators, gate valves, distributors and other devices from our offer. Also for transporting materials other than those listed above.