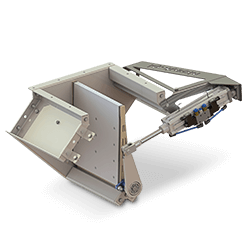

The distribution flap is lined with PEHD plastic, which extends the period of trouble-free exposure of the device.

If additional protection of the device is required. Recommended in the case of a very large stream of medium, or when we are not sure whether the charge is perfectly vertical.

We offer gate valves for tank and conveyor valves with ATEX II 2D and 3D certificates, enabling the installation of devices and safe operation in zones with an increased risk of explosive atmospheres Electrically controlled, pneumatically or manually compliant with the ZPR and NZZ series with components adapted to work in the EX zone

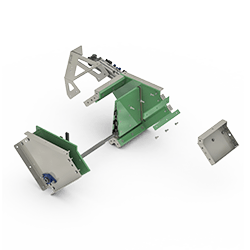

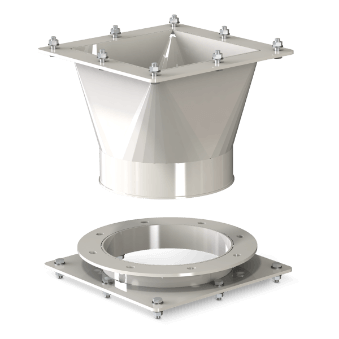

Our devices, regardless of their type series, can be equipped with fittings that enable trouble-free charging of the device, as well as its proper emptying. The connecting elements, made according to three termination standards, determine how they are installed in your piping system:

Fittings are available in standardized versions, as well as are made according to individual needs, adapted to the situation in your facility.

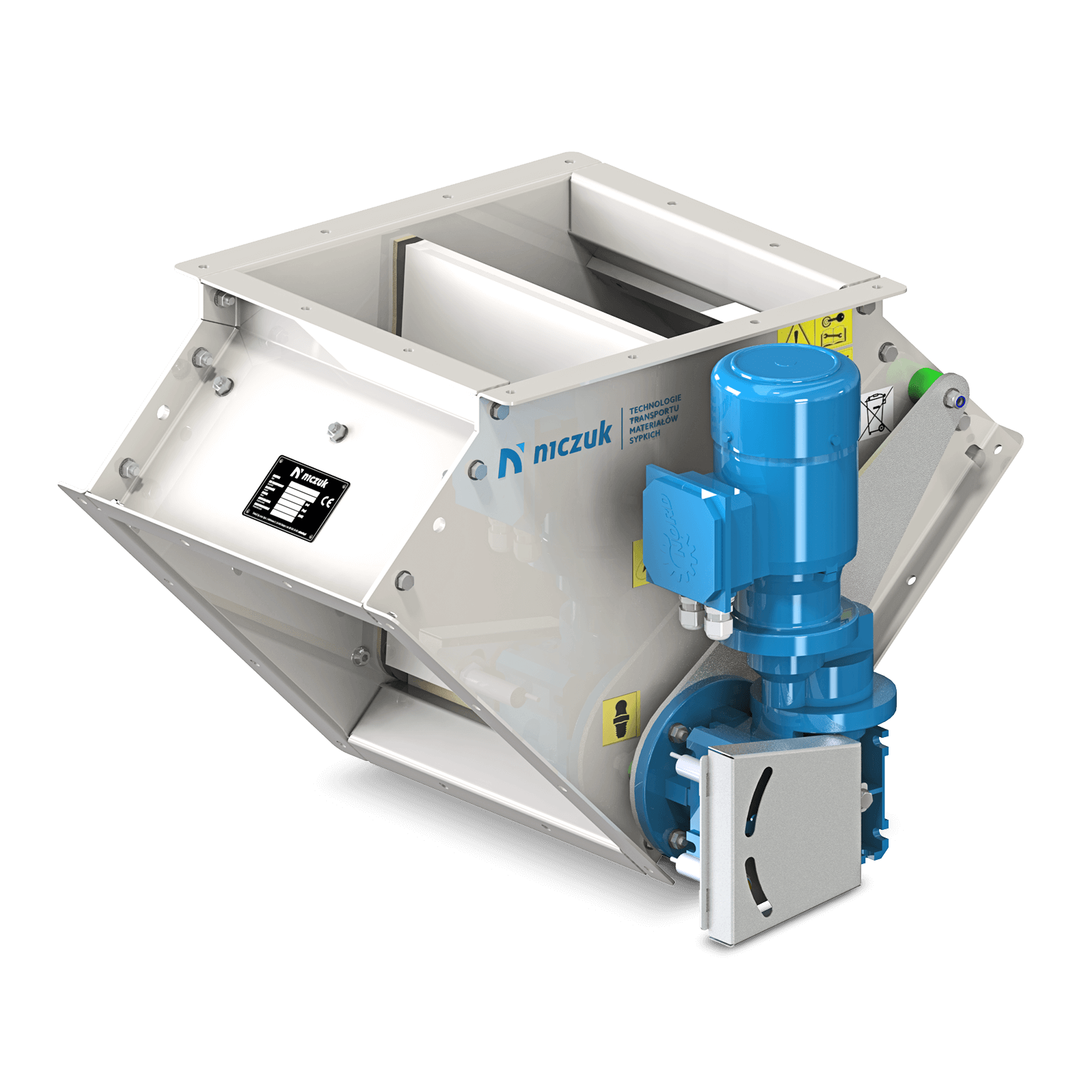

Distributors are designed to change the route of the transported medium, according to the customer's needs and his technological requirements.

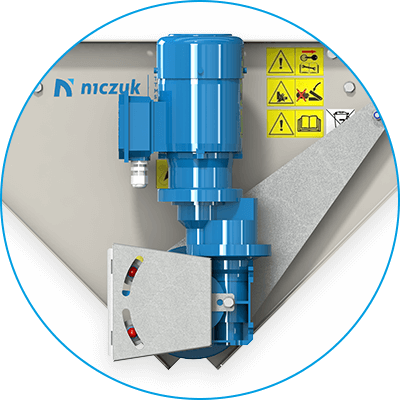

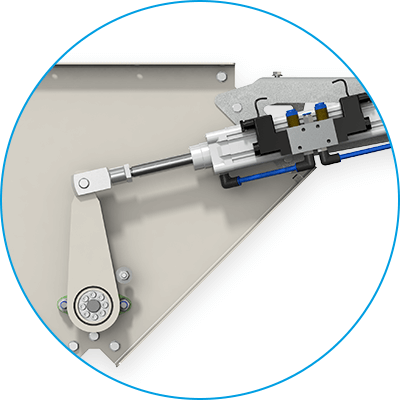

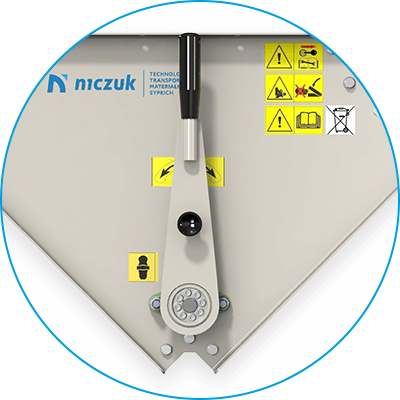

Types of splitter disc drives: - mechanical (manual), - electric - worm geared motors NORD, - pneumatic - actuators from FESTO, HAFNER in accordance with ISO6431. The design of the distributorss provides the possibility of dividing the transport route into two lines

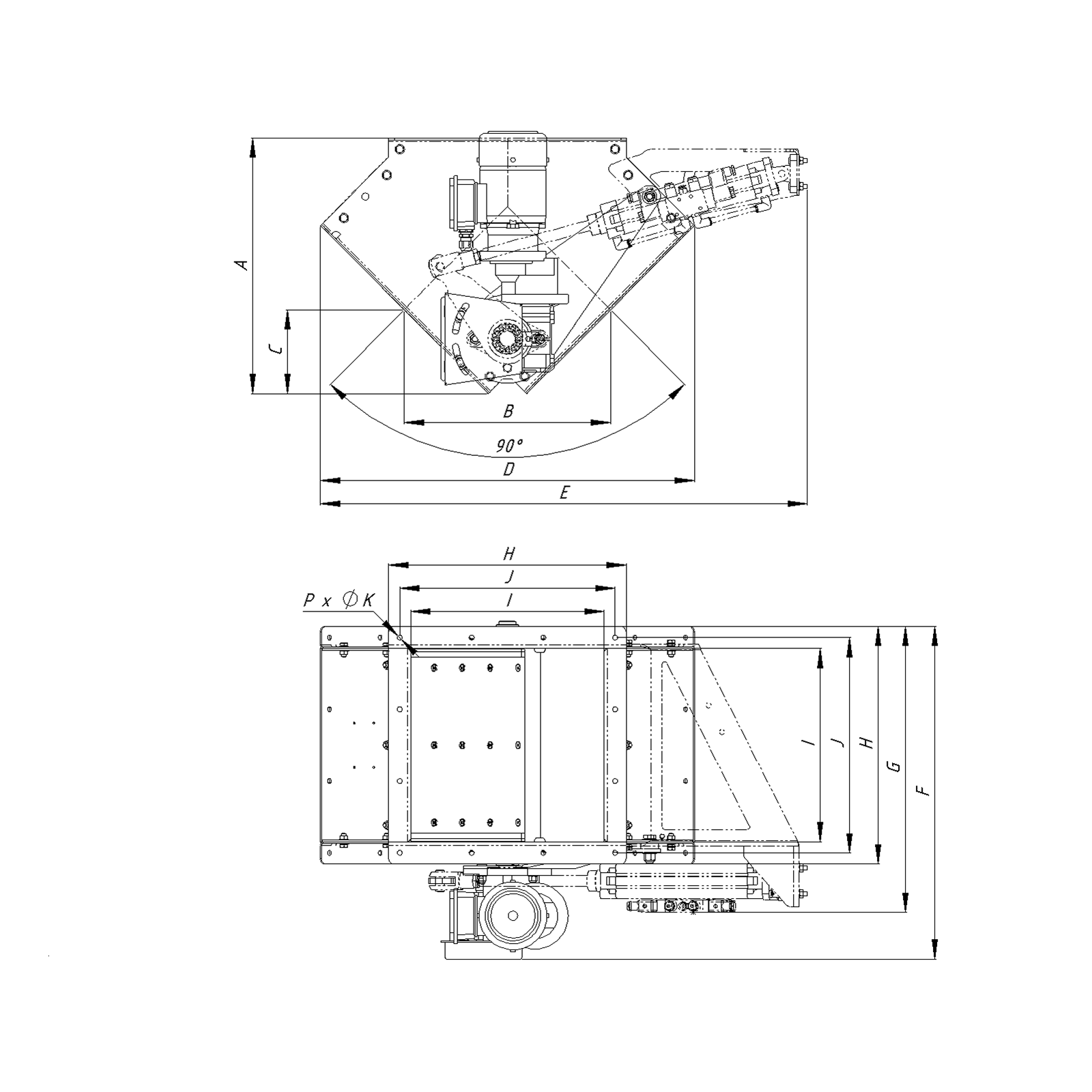

The product is available in a symmetrical version, with an angle between chutes equal to 90°. The distributors design allows the replacement of internal seals, separation plate (flaps) and axles. The design of the product is fully demountable, which allows easier and faster replacement of the shaft. The advantage of the distributor is its total dustproofness. The product is made of galvanized steel or S235 powder coated steel as standard. An alternative is to make the distributor from acid-resistant and stainless steel.

| Typ | Designation | A [mm] | B [mm] | C [mm] | D [mm] | E [mm] | F [mm] | G [mm] | H [mm] | I [mm] | J [mm] | Ø K [mm] | P [szt.] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | RDS-200-E | 332 | 280 | 99 | 478 | - | 465 | - | 280 | 200 | 240 | 10.5 | 8 |

| 200 | RDS-200-R | 332 | 280 | 99 | 478 | - | - | 351 | 280 | 200 | 240 | 10.5 | 8 |

| 200 | RDS-200-P | 332 | 280 | 99 | - | 720 | - | 351 | 280 | 200 | 240 | 10.5 | 8 |

| 250 | RDS-250-E | 367 | 295 | 117 | 528 | - | 515 | - | 330 | 250 | 290 | 10.5 | 8 |

| 250 | RDS-250-R | 367 | 295 | 117 | 528 | - | - | 401 | 330 | 250 | 290 | 10.5 | 8 |

| 250 | RDS-250-P | 367 | 295 | 117 | - | 743 | - | 401 | 330 | 250 | 290 | 10.5 | 8 |

| 300 | RDS-300-E | 427 | 359 | 134 | 627 | - | 565 | - | 380 | 300 | 340 | 10.5 | 8 |

| 300 | RDS-300-R | 427 | 359 | 134 | - | - | - | 456 | 380 | 300 | 340 | 10.5 | 8 |

| 300 | RDS-300-P | 427 | 359 | 134 | - | 845 | - | 456 | 380 | 300 | 340 | 10.5 | 8 |

| 350 | RDS-350-E | 463 | 373 | 152 | 677 | - | 615 | - | 430 | 350 | 390 | 10.5 | 12 |

| 350 | RDS-350-R | 463 | 373 | 152 | 677 | - | - | 507 | 430 | 350 | 390 | 10.5 | 12 |

| 350 | RDS-350-P | 463 | 373 | 152 | - | 861 | - | 507 | 430 | 350 | 390 | 10.5 | 12 |

| 400 | RDS-400-E | 519 | 430 | 170 | 770 | - | 665 | - | 480 | 400 | 440 | 10.5 | 12 |

| 400 | RDS-400-R | 519 | 430 | 170 | 770 | - | - | 556 | 480 | 400 | 440 | 10.5 | 12 |

| 400 | RDS-400-P | 519 | 430 | 170 | - | 976 | - | 556 | 480 | 400 | 440 | 10.5 | 12 |

Thanks to our experienced team of designers we are able to carry out projects involving non-standard chain and screw conveyors as well as bucket elevators, gate valves, distributors and other devices from our offer. Also for transporting materials other than those listed above.